How to use predictive modeling technology to proactively discover and mitigate risks

AI-driven predictive modeling software can lay a powerful foundation for a proactive approach to de-risking everything from new network design, equipment inspections, vegetation management, and beyond. AI-driven software can handle the bulk of the legwork in taking a first pass at flagging risks that meet custom thresholds your team sets. AI can process enormous volumes of data, as well as efficiently and consistently navigate relationships between different data sets. As a result, it can be a formidable force-multiplier to manual inspections by directing precious expertise where it’s needed most.

However, a key advantage is that software can cover your entire network at once, not just a few hundred poles at a time, giving you the confidence that your team’s attention is exactly where it needs to be. Discovering risks digitally also offers flexibility to define and reset risk thresholds, simulate different weather conditions and mechanical variables, and easy-to-audit outputs you can share to measure outcomes and validate your approach.

1. Using data sources you’re likely to have already, populate a digital model of your network.

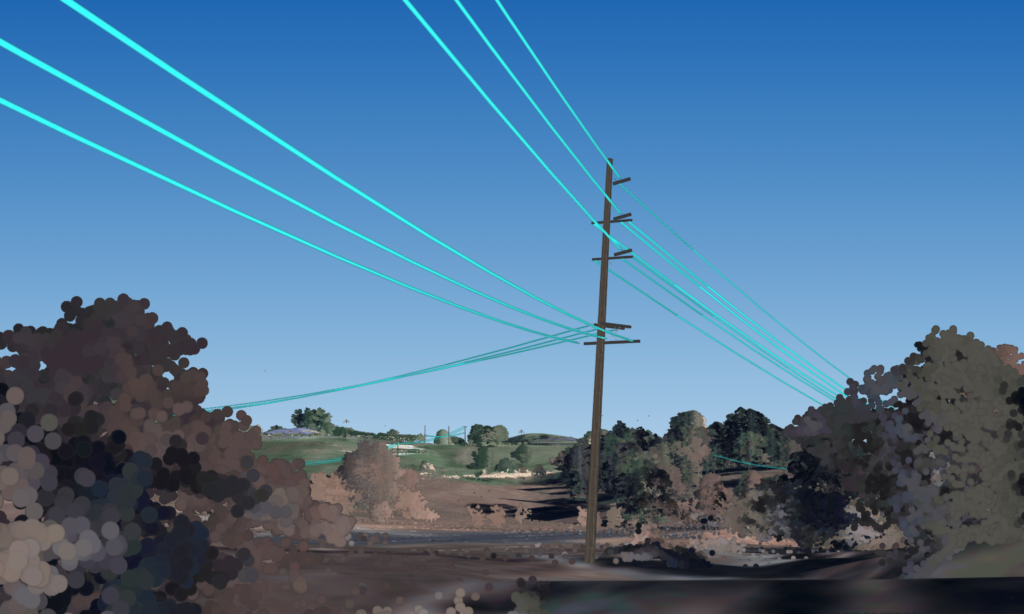

Data sources include GIS, LiDAR, imagery, pole libraries, construction standards, and more. Many utilities are looking to purpose-built software to build hyper-accurate, custom-engineered network models that are geometrically and behaviorally identical to your real-life assets, so every asset bends, sags, deforms, and sways exactly the same way your real-life assets would in response to stimuli like heat and wind.

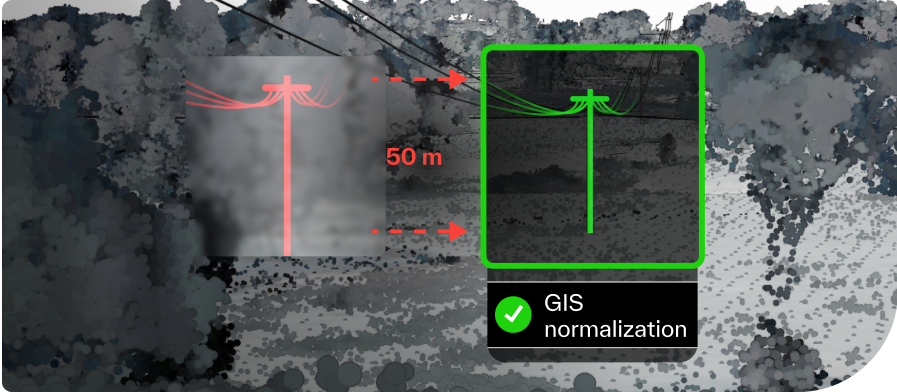

2. Correct data errors and confirm the exact location of every asset, vegetation type, and clearance object.

The combination of data sources in a digital model can automatically, and quickly, reveal and fix errors in your data. This means that you will never again send a team into the field for maintenance to the wrong location.

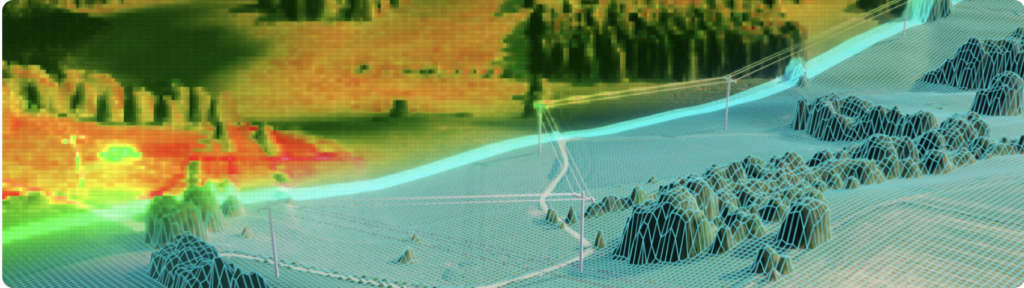

3. Conduct in-platform surveys, including severe-weather stress tests.

In Neara’s software, you can simulate hundreds of environmental and mechanical variables and get a detailed report on how every single asset will respond. Outputs include pole loading risks, areas where conductor clashing is likely, roadway clearance breach risks, vegetation fall-in, and encroachment risks. Then, findings at the individual asset level roll up to system-wide assessments you can use to demonstrate improved reliability and resilience clearly.

4. Execute triage according to rigorously and uniformly defined risk thresholds.

Identifying risks digitally means you will find orders of magnitude more of them in one “survey.” If that sounds overwhelming, rest assured that for the first time, you can tier risks according to criteria you define by urgency and impact. This step is critical in clarifying priorities and building transparency around a proactive approach.

At this stage, many realize that several manually flagged tier-one risks no longer make the cut. And among those that do, there’s often a great deal of variability in actual urgency — if your tier-one threshold is an eight-foot clearance, you probably want to prioritize the one just two inches from a line instead of 7.9 feet away.

5. Run risk-reduction analyses, execute remediation and measure outcomes.

Based on risks you’ve identified, execute analyses in minutes and hours that would otherwise take months or more in the field. For example, show exactly where you need to replace wooden poles with composite ones and where it’s likely sufficient to simply add stays. Find the perfect route for net new network design. Explain every dollar of your vegetation budget, highlight specific spans where reconductoring will help you better prepare for a heat wave, and, most importantly, demonstrate that your approach is effective.