Equipment Inspections

Stress-test and diagnose every single asset across the full lifecycle from repair, replacement, and reconfiguration without setting foot in the field and focus field time on validation and triage. Digitally inspect your equipment so you can see how every asset will respond to simulated gale force winds, flash floods, and more when you can’t have your team out for the real thing.

- Prevent more outages and safety incidents by keeping your equipment in its best shape.

- Stop manually answering the same hundreds of questions per pole. Leave the manual heavy lifting to AI and empower your team to focus on the right questions about improving resilience.

- Be the first to know about critical vulnerabilities by simulating hundreds of mechanical and environmental variables, from heat waves to line tensioning, so you can see the unforeseen and take preventive action.

Leave failure and ignition risks nowhere to hide — even the ones the naked eye can’t see.

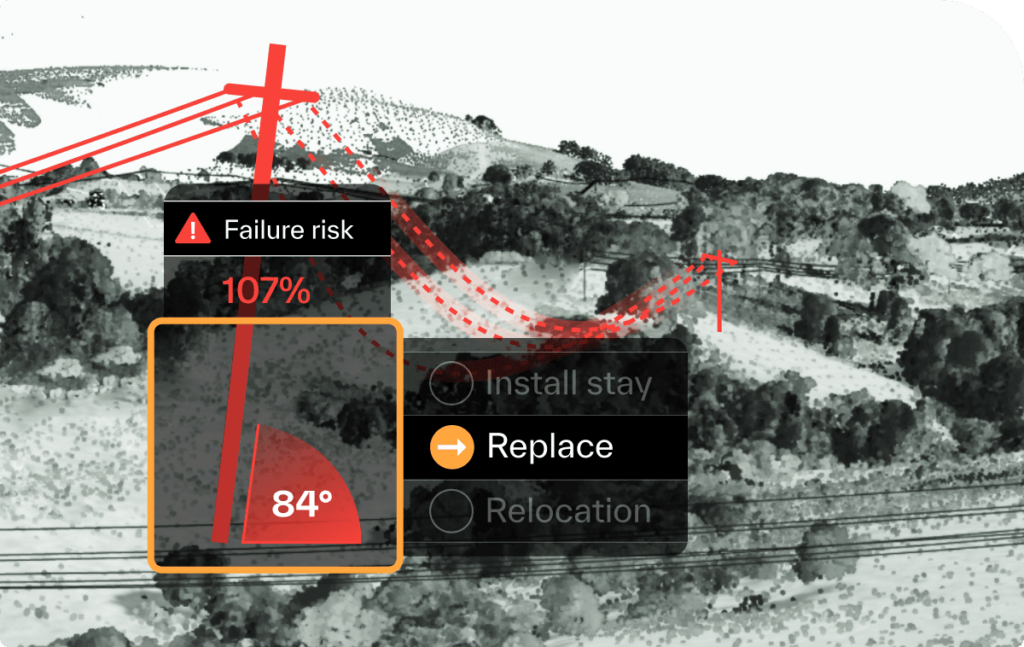

Replace, repair, or reconfigure?

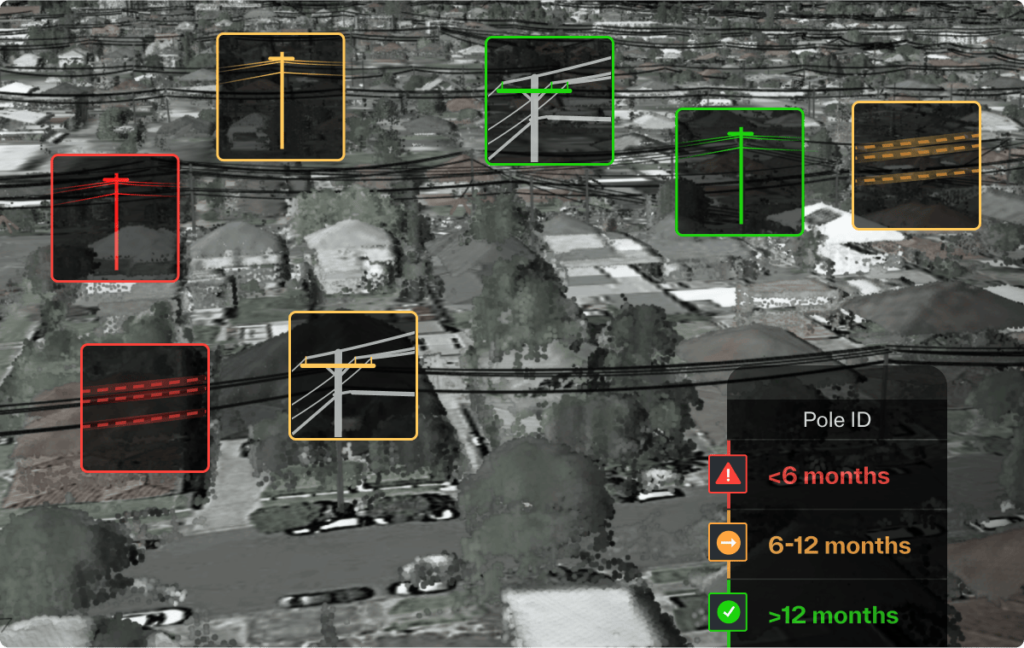

Look to your network model for a 90% automated triage plan to get every asset in shape. Whether you need to replace, repair, reconfigure, or relocate equipment, it’s easier than ever to see which equipment needs your attention and diagnose the right next step, whether that’s replacing a concrete pole with steel, adding a stay, or moving a pole 10 yards away. Measure variables such as pole height, lean, bend, and conductor tension with precision at scale — and from there, stress-test your equipment to find and fix your weakest links.

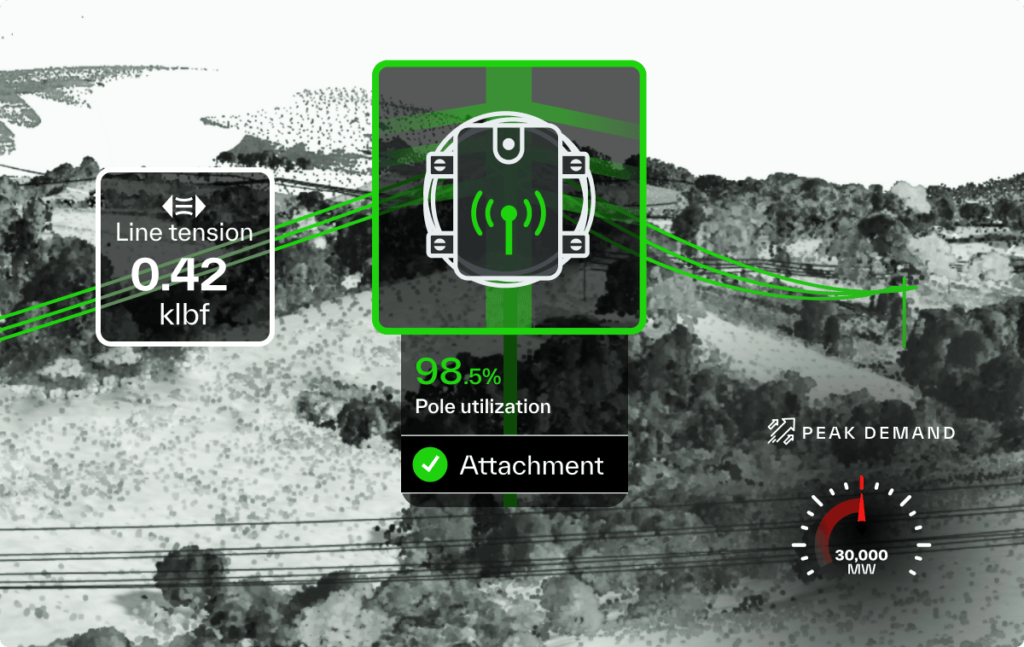

Get pole load “just-right”

Between broadband joint use and expanding carrying capacity, there are more reasons than ever to maximize pole utilization — but the consequences of going too far can be catastrophic. Your network model helps you find the ideal pole load so that your efficiency never becomes the enemy of reliability or safety. Stress-test every pole in your network against hundreds of mechanical and environmental variables to find the right loading formula that supports network productivity without risking failure.

Flag buddy poles

You can only maintain the poles you’re aware of. But the trouble is you’re liable for all of them. Automatically detect and flag double poles based on attributes like pole height, type, and spatial relationships using your network model so that you have a clear lay of the land — meaning you can allocate your maintenance work orders with confidence across every asset that needs attention, not just the ones in your GIS.

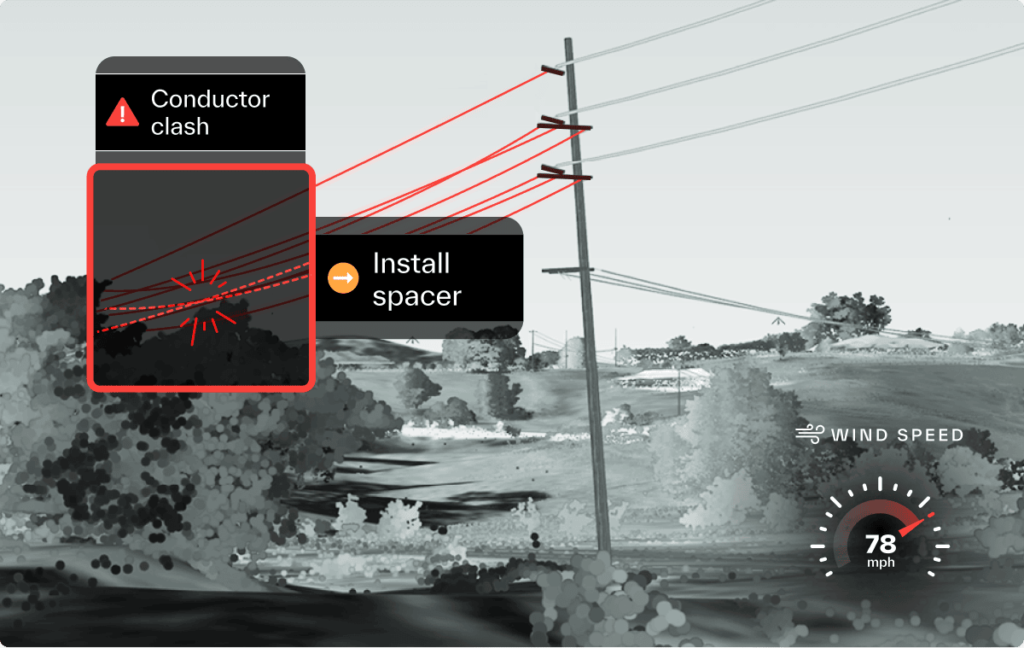

Safeguard against conductor clashing

Between clashing and galloping, you know your conductor behavior can change on a dime in different conditions. But relying on field surveys to inspect conductors means you don’t get to see exactly where problematic behavior is most likely and most severe. Pinpoint mechanical and structural flaws such as tension imbalances across every conductor in your network and layer on prime wildfire conditions or a hailstorm to see exactly where you need to take action against short-circuiting, equipment failure, and worse.

Understand cumulative asset stress

Go beyond inspecting assets as they stand today — and even beyond how they’ll fare in high winds, an ice storm, or a heat wave. Factor in how your asset integrity changes with time as your equipment experiences cumulative stress, such as cable creep. Simulate creep curve according to custom increments based on the actual age of your assets, and layer in as many other variables as you see fit for the most thorough inspections and best lifecycle decisions as a result.

Stay ahead of asset failure with network-wide FEA

Calculate strain and stress on all network components, including poles, spans, cross-arms, insulators, pins, and braces. Understanding the efficacy and useful life of all of your assets helps you detect hidden risks, prioritize replacements and repairs, and definitively evaluate which poles are at capacity and which can carry more load. AI-assisted FEA in your digital network model is your roadmap for keeping every asset at peak performance, no matter where you are in the lifecycle.